Product Selector

Our portable HEPA air purification solutions improve air quality and reduce risks posed by dangerous airborne particles and compounds.

Select the right product for your application below.

Filter

Filter By

Clear Filters

Application

Product Type

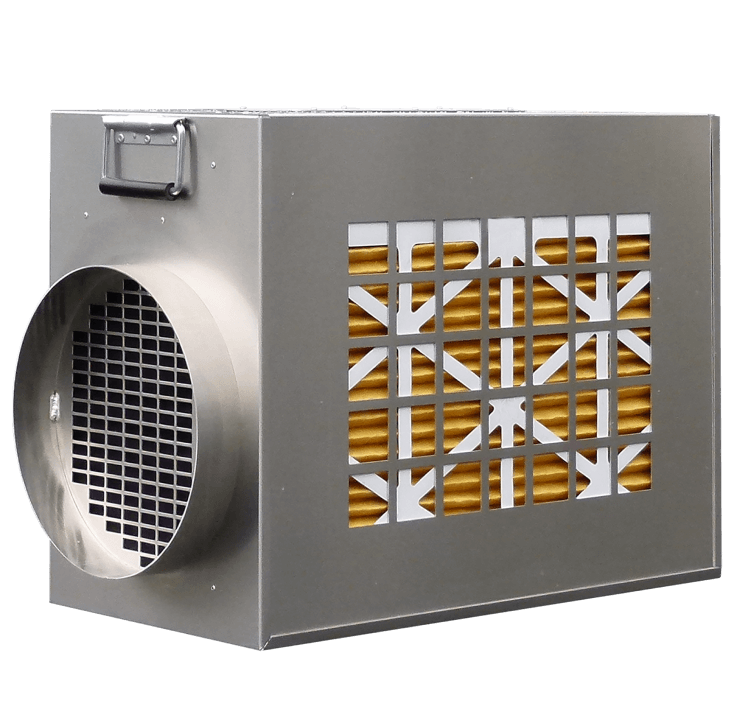

Consumables

-

-

-

Size

-

Depth

-

Frame/Header Material

-

Capacity

-

Efficiency

-

-

-

Size

-

Frame/Header Material

-

Capacity

-

Efficiency

-

MERV-Rating

-

-

-

Size

-

Capacity

-

-

-

-

-

-

Size

-

-

-

Size

-

Depth

-

Frame/Header Material

-

MERV-Rating

-

-

-

-

-

-

Size

-

-

-

-

-

-

By Model Number

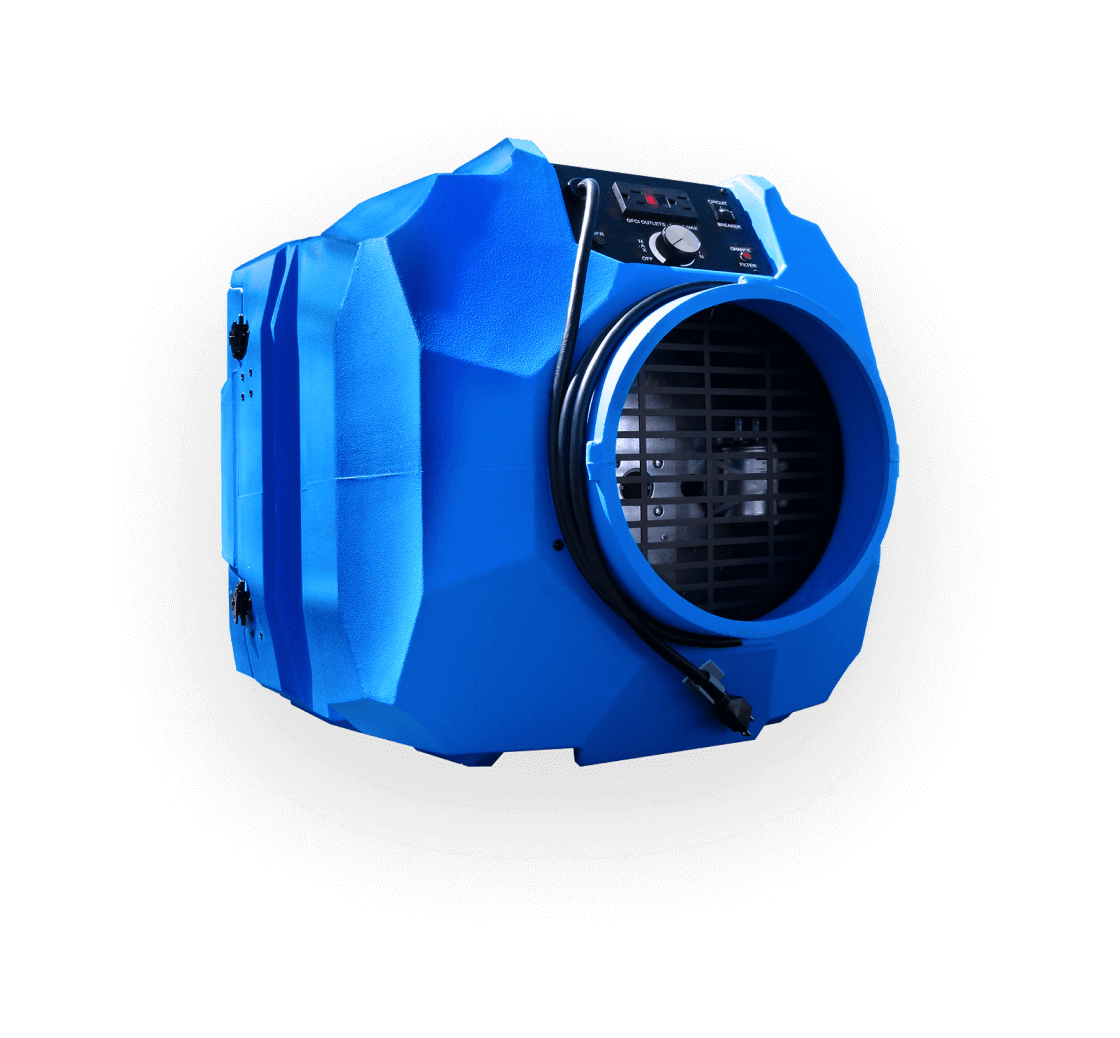

OA600 Nitro Series

Negative Air Machines

OA600 Series

Negative Air Machines

OA1000 Series

Commercial & Medical Air Purifiers Negative Air Machines

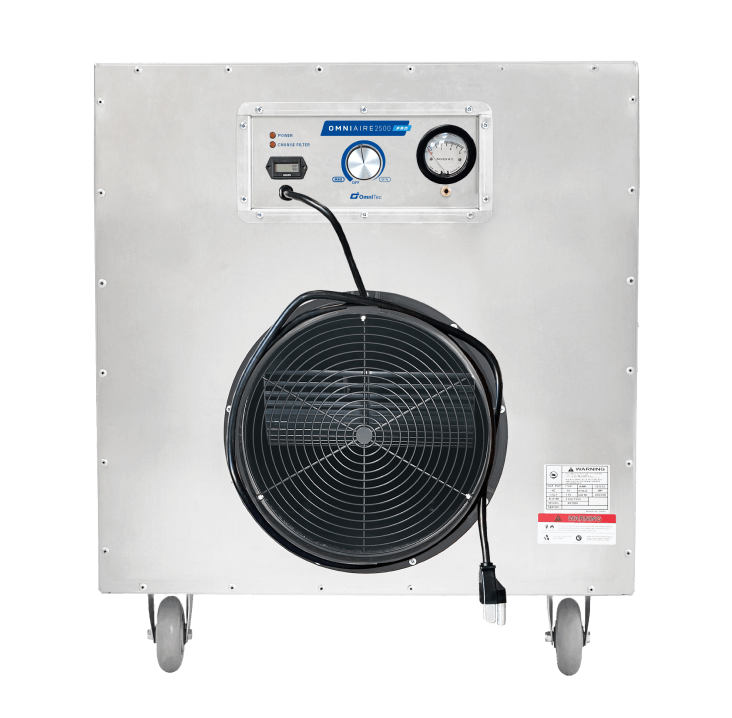

OA2000 Series

Negative Air Machines

OA2200 Series

Negative Air Machines

OA2500 Series

Negative Air Machines

OmniClean Series

Commercial & Medical Air Purifiers

OA1200 PAC & OA1600 PAC

Commercial & Medical Air Purifiers

Pressure Monitors

Pressure Monitors

Surface & Air Cleaners

Surface & Air Cleaners

Water Filtration

Water Filtration