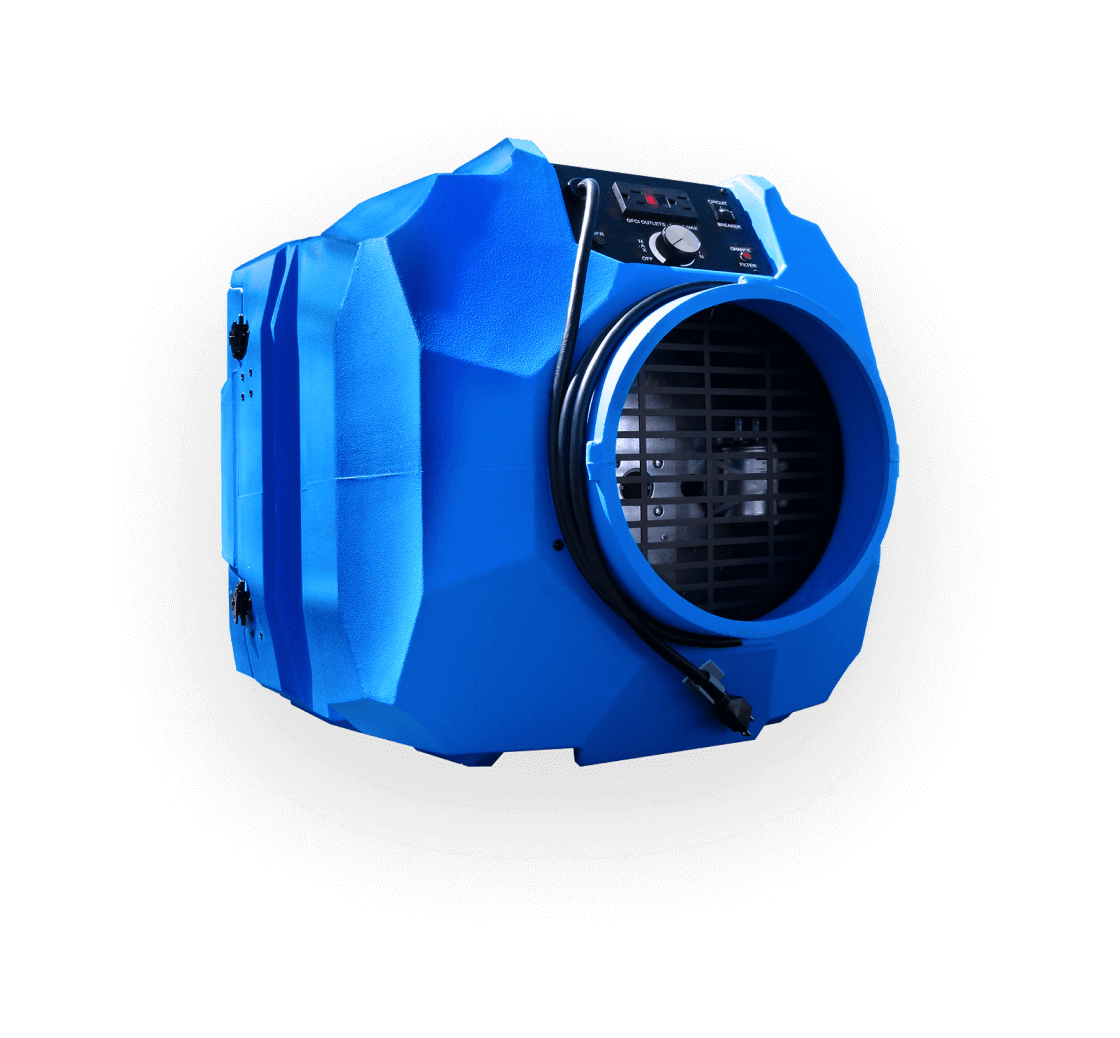

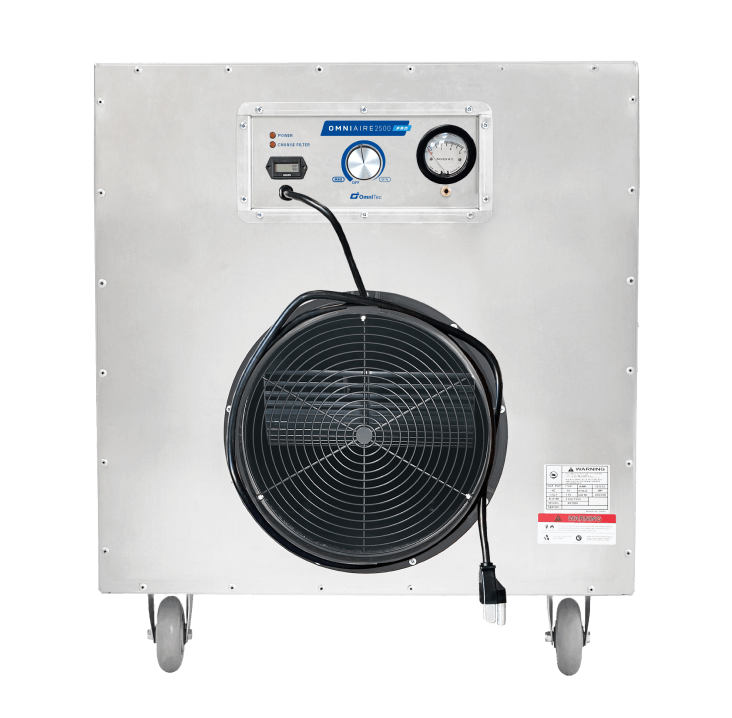

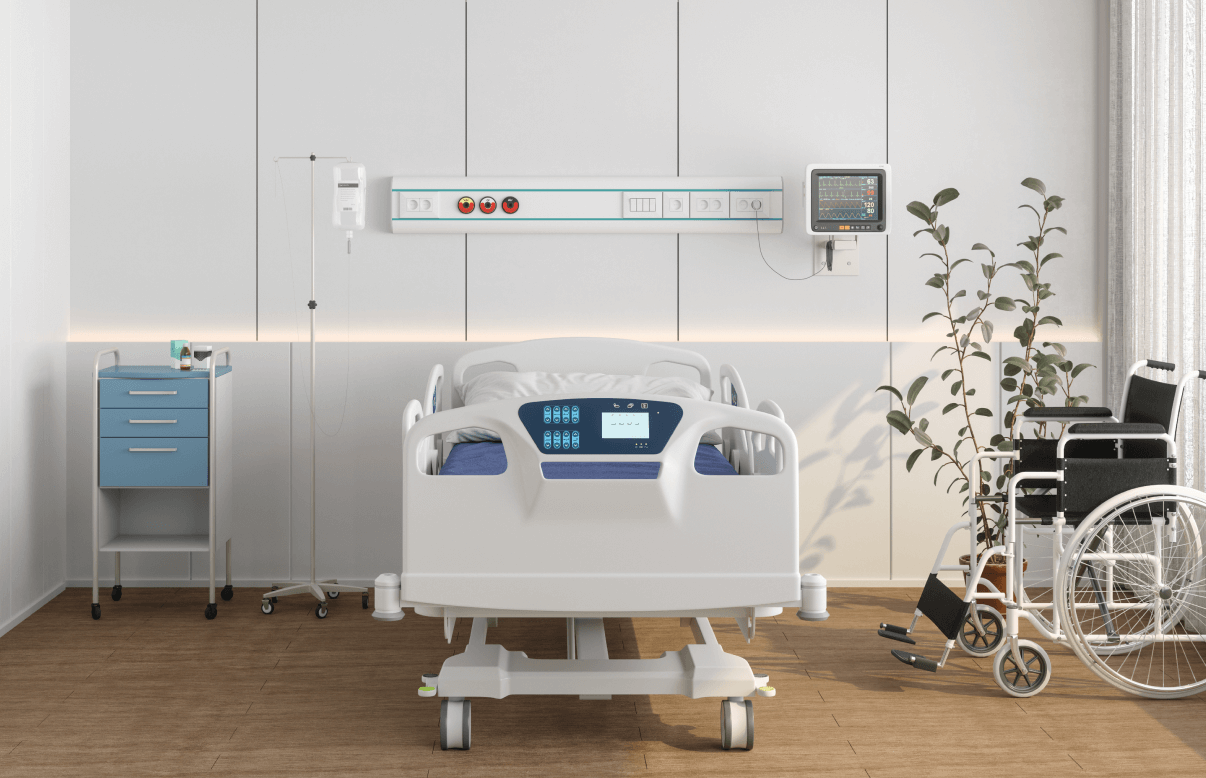

The OmniAire 600 Nitro Series rotomolded negative air machine and air scrubber that combines compact portability and rugged design with HEPA technology. It effortlessly cleans the air and, with variable fan speed control, delivers negative or positive pressure compliance in spaces as large as 9000 cubic feet at four air changes per hour.

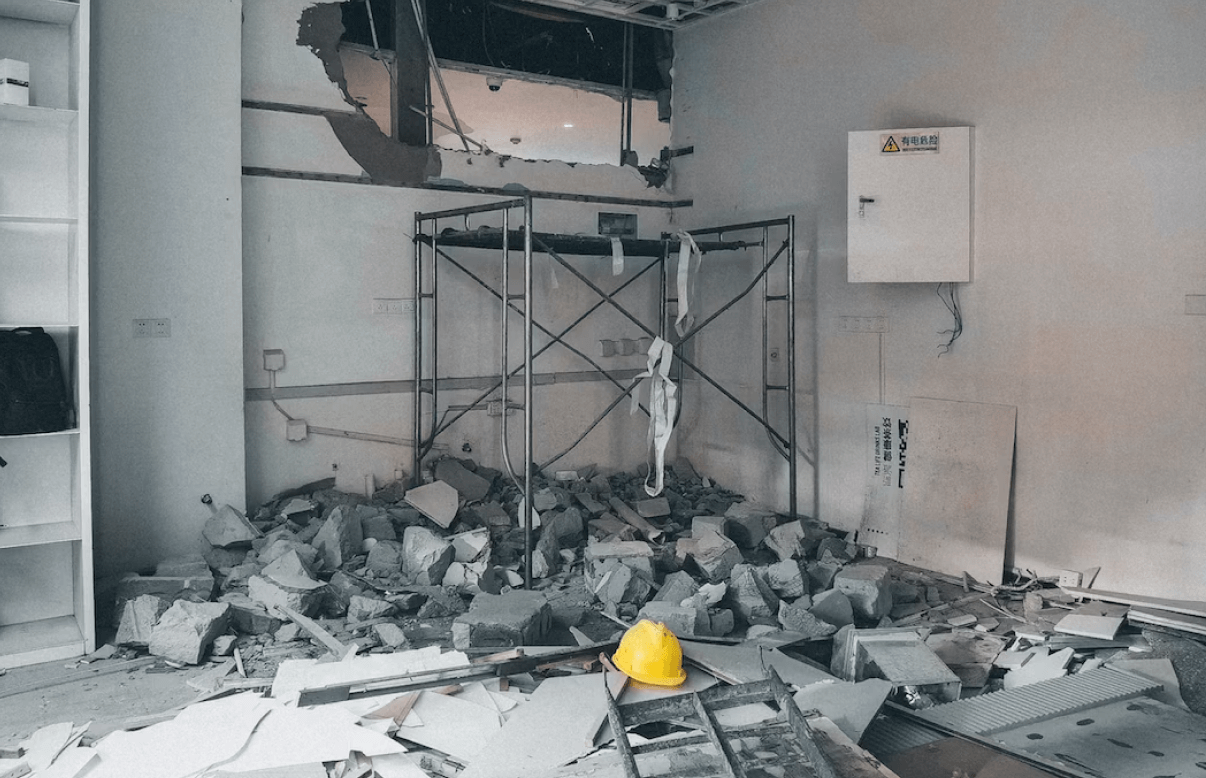

The OA600 Nitro Series is known for its lightweight, stackable build that saves time and space during setup and storage, making them essential on abatement job sites and in industrial environments, especially in cramped and confined spaces.