A Guide to Negative Pressurization

Why Pressurization Matters

Airflow control is a critical element of infection prevention in healthcare construction and renovation. Proper ventilation not only helps remove dust and debris but also plays a vital role in preventing airborne contaminants from spreading into patient care areas.

A key strategy is the use of negative pressurization, where airflow is directed into a contained workspace and prevented from escaping. This directional airflow protects surrounding areas by ensuring contaminants are contained within the construction zone.

How to Define Pressure Relationships

Understanding pressure relationships starts with perspective:

- If air is flowing into a room from the corridor, the room is considered negative relative to the corridor.

- If air flows out of a room into the corridor, the room is positive.

When setting up containment zones, the vantage point should always be the workspace being controlled.

Class-Specific Pressurization Requirements

Class III Precautions

- Workspaces must be maintained at neutral to slightly negative pressure.

- Remove or isolate both supply and return air diffusers.

- Use exhaust systems that meet Class IV standards if full isolation isn’t possible.

Class IV and V Precautions

- Entire workspace must remain negatively pressurized at all times.

- Air must flow in one direction—from clean areas into the construction zone—forming a cascading airflow through the anteroom and into the workspace.

Requirements:

- Exhaust air must be directed outdoors and located at least 25 feet from any air intakes, doors, or windows.

- If exhausting indoors, exhaust must pass through a verified HEPA filtration system.

- HEPA filters must be tested and proven to have at least 99.97% efficiency at project setup and routinely verified during work.

- Exhausting into HVAC returns, restroom exhaust systems, or other shared ducts is prohibited.

- Visual pressure monitors must be installed outside containment areas to continuously verify pressurization.

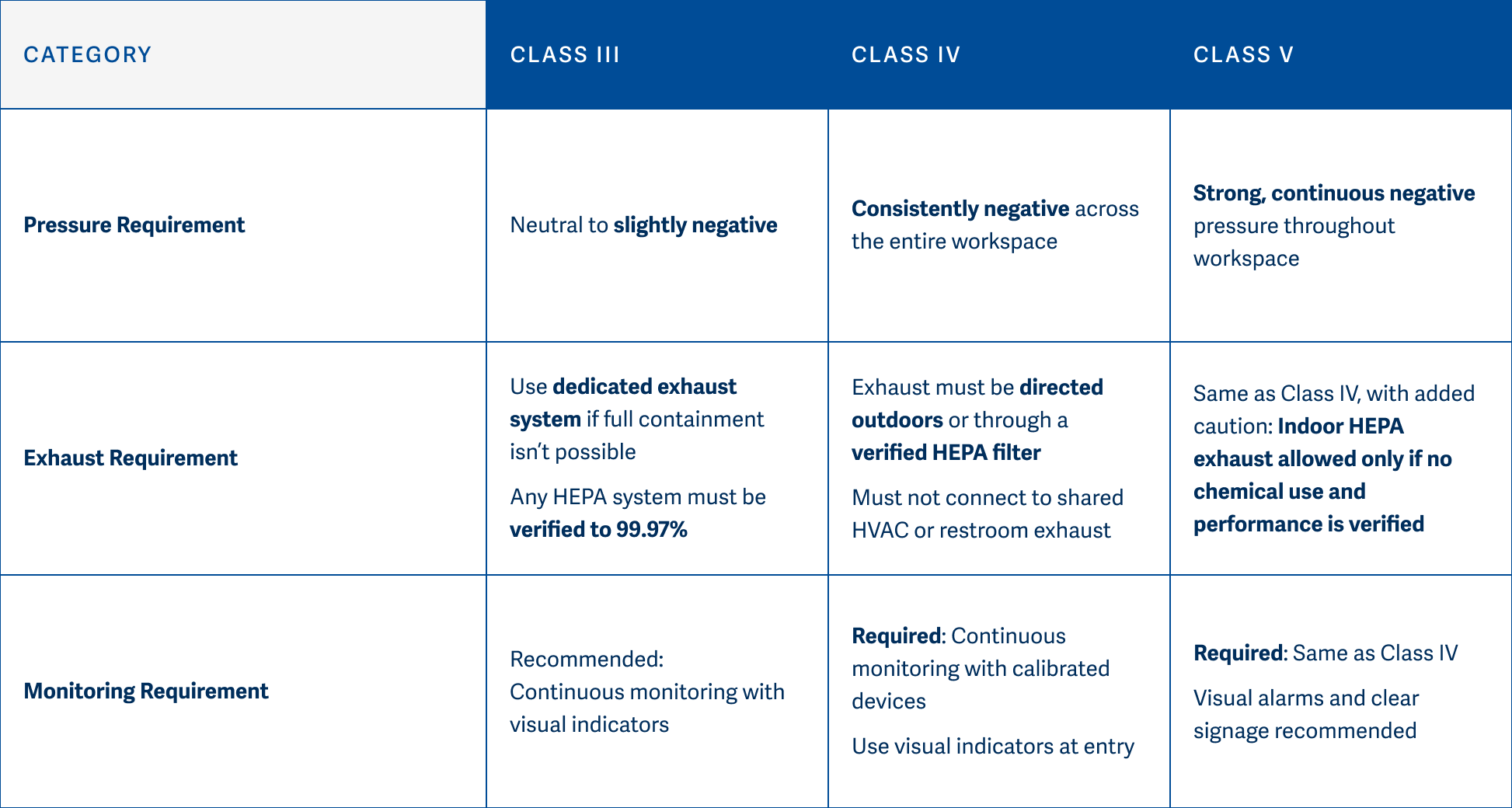

ICRA 2.0 Pressurization Requirements Overview

Best Practices for Maintaining Negative Pressure

- Maintain directional airflow from outside → anteroom → workspace.

- Monitor pressure levels consistently using approved and calibrated manometers or digital differential pressure monitors.

- Follow recommended pressure differentials guidelines like:

- FGI: recommends ≥ –0.03” inches of water column (in H₂O) in high-risk areas.

- APIC: suggests –0.02 to –0.04” inches of water column (in H₂O).

Understanding and maintaining proper negative pressure relationships is essential for infection control during healthcare construction. Always ensure airflow moves from clean to dirty areas, use verified HEPA-filtered exhaust systems isolated from the HVAC, and continuously monitor pressurization to protect patients, staff, and ensure project compliance.