TrueCFM™ is

Our Standard.

Omni CleanAir provides true transparency to CFM Rating.

In the realm of hazardous work environments, where dangerous particles must be contained and removed with precision, Omni CleanAir proudly presents the TrueCFM™ promise. Our stated CFM rating for all Omni CleanAir negative air machines, air scrubbers, and air purifiers provides a new standard for reliability and performance.

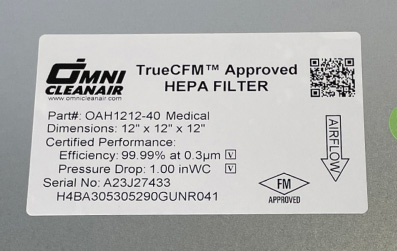

Opting for Omni CleanAir goes beyond buying a product; it signifies a commitment. The effectiveness of our machines is assessed through the volume of treated air, measured in Cubic Feet per Minute (CFM), and the frequency at which air is turned over, or Air Changes per Hour (ACH). Our TrueCFM rating ensures that the specified CFM rates for our machines in combination with our certified HEPA filters are not just numbers on a page. These rates are carefully verified, tested, and certified to uphold the most stringent standards of air purification.

The Science Behind Our Promise

Understanding the required airflow is crucial in various scenarios, such as asbestos abatement, patient isolation, or silica dust containment.

Airflow is commonly measured in Cubic Feet per Minute (CFM) or Cubic Meters per Minute (CMM), representing the machine’s output under normal operation. A higher CFM indicates the machine’s ability to treat larger spaces at specified Air Changes per Hour (ACH).

The required CFM should be determined based on the size of the containment space and the necessary air changes or corresponding differential pressure in a negative pressure containment application. For instance, the OSHA ASBESTOS STANDARD 29 CFR 1926.1101 specifies that portable air ventilation systems providing negative air pressure and air removal must be equipped with a HEPA filter. The number and capacity of units needed depend on the size of the area to be ventilated.

It’s important to note that not all CFM specifications are created equal. Understanding how manufacturers specify both airflow rate and efficiency is critical. This knowledge ensures that the chosen system meets the specific requirements of the application, preventing potential complications and ensuring compliance with relevant standards.

Precision Engineering for Maximum Performance

It is essential to determine the appropriate airflow to effectively treat the space and meet the air quality standards for the specific application. Ambiguous or misleading specifications can significantly complicate this process, potentially causing the project to fall short of compliance requirements. Our Air Scrubbers, Air Purifiers, and Negative Air Machines are meticulously engineered to deliver optimal CFM when paired with our Omni CleanAir HEPA Filters. From the design phase to manufacturing, we prioritize precision to ensure that our products consistently outperform industry standards.

Understanding the Relationship Between CFM and ACH

Air Changes per Hour (ACH) is a straightforward metric that denotes how many times the entire air volume of a space should be treated by the machine in the span of one hour. According to OSHA 1926.1101, a minimum of 4 air changes per hour is required, translating to a single air change every 15 minutes.

When working with the size of a containment space (typically measured in cubic feet or ft³), knowing the necessary ACH allows for the calculation of the required CFM. Conversely, having the CFM value and the volume of the space enables the calculation of the resulting ACH. This reciprocal relationship ensures a comprehensive understanding of the air treatment dynamics within a given space.

CFM is a Measure of Velocity, not necessarily a Measure of Quality.

While CFM serves as a velocity metric, it doesn’t inherently reflect air quality. In the context of a negative air machine, CFM primarily gauges the machine’s power without directly assessing its particle-capturing effectiveness. Ideally, the volume of treated or filtered air should closely align with the air volume passing through the machine or system. For instance, a machine operating at 1,000 CFM with a 99.99% efficient HEPA filter should deliver processed (filtered) air at a rate of 999.9 CFM, often referred to as Clean Air Delivery Rate (CADR).

However, the actual CADR may be lower due to various factors. If there are pathways for air to circumvent or bypass the HEPA filter, the processed air treated by the HEPA might be less, resulting in a diminished CADR. Manufacturers solely providing CFM values may overlook the true amount of treated air delivered. At Omni CleanAir, our machines are designed with secure HEPA, sufficiently sealed to prevent air from bypassing the filter, ensuring that all processed air is effectively treated.

Maintaining Negative Pressure adds Complexity to your Requirements.

A negative pressure containment zone is one where the pressure inside the zone is lower than the pressure outside the zone. This prevents the contaminated air from inside the zone from escaping containment. These containment zones are used in a variety of applications, from patient isolation to asbestos abatement, and in some of these cases, maintaining negative pressure is a requirement 100% of the time the work is being performed.

A containment space can be placed under negative pressure by placing a negative air machine inside the space and ducting out the treated air. When a negative pressure zone is required, regulations often specify the need to record the pressure differential and trigger alarms when the differential falls below a threshold.

HEPA Filters You Can Trust

Customizable Solutions

True Transparency

Your Trust, Our Priority

TrueCFM is not just a verifiable rating; it’s a symbol of our commitment to your success. Omni CleanAir stands by the promise that when you choose our products, you’re choosing real, measurable, and reliable clean air solutions. Unlike some companies, transparency of the specifications is key to our offering. Explore the TrueCFM advantage with Omni CleanAir and enjoy the confidence of true transparency.