Navigating the Dangers of Crystalline Silica Exposure in the Workplace

Crystalline Silica, a prevalent mineral found in quartz, sand, gravel, clay, granite, and various rock formations, has become a focal point of concern due to its widespread presence and the associated health risks it poses.

According to reports from the Occupational Safety and Health Administration (OSHA), over 2 million individuals are regularly exposed to silica dust in their workplaces.

This exposure predominantly occurs during activities like cutting, grinding, drilling, and chipping of natural and manufactured stone products, as well as various concrete-related tasks. The resulting particulates are released into the air, significantly expanding the scope of potential exposure beyond just the workers directly involved in these activities. Those in close proximity to such operations are also at risk of inhaling silica dust.

Even limited exposure to silica dust can have detrimental effects on respiratory health. The inhalation of these particles can lead to the formation of scar tissue in the lungs, impairing their ability to efficiently absorb oxygen. Prolonged exposure can result in various forms of Silicosis, including chronic, classic accelerated, and acute manifestations, all of which contribute to the development of a debilitating lung disease.

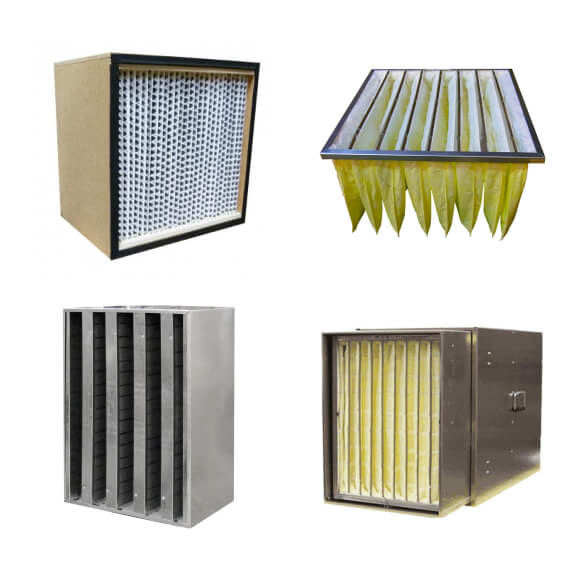

Silica is encountered in various industries and processes, such as demolition, countertop manufacturing, and the production of materials like quartz, granite, aggregate for concrete, bricks, terracotta tiles, and sandstone. In order to create safer workspaces and address the issue of silica dust containment, negative air machines equipped with High-Efficiency Particulate Air (HEPA) filtration have become instrumental. These machines create a negative pressure air space, effectively drawing in fine dust particulates, which are then captured by the HEPA air filter.

HEPA filters play a crucial role in removing fine particulates from the air, thereby establishing an environment that meets safety standards. This is particularly essential for workers in silica-exposed industries, including those involved in concrete grinding, countertop manufacturing, and countertop installation. The use of HEPA filtration not only safeguards the health of workers but also contributes to the overall mitigation of potential respiratory hazards associated with crystalline silica exposure. It underscores the importance of proactive measures in ensuring occupational health and safety in environments where silica dust is prevalent.