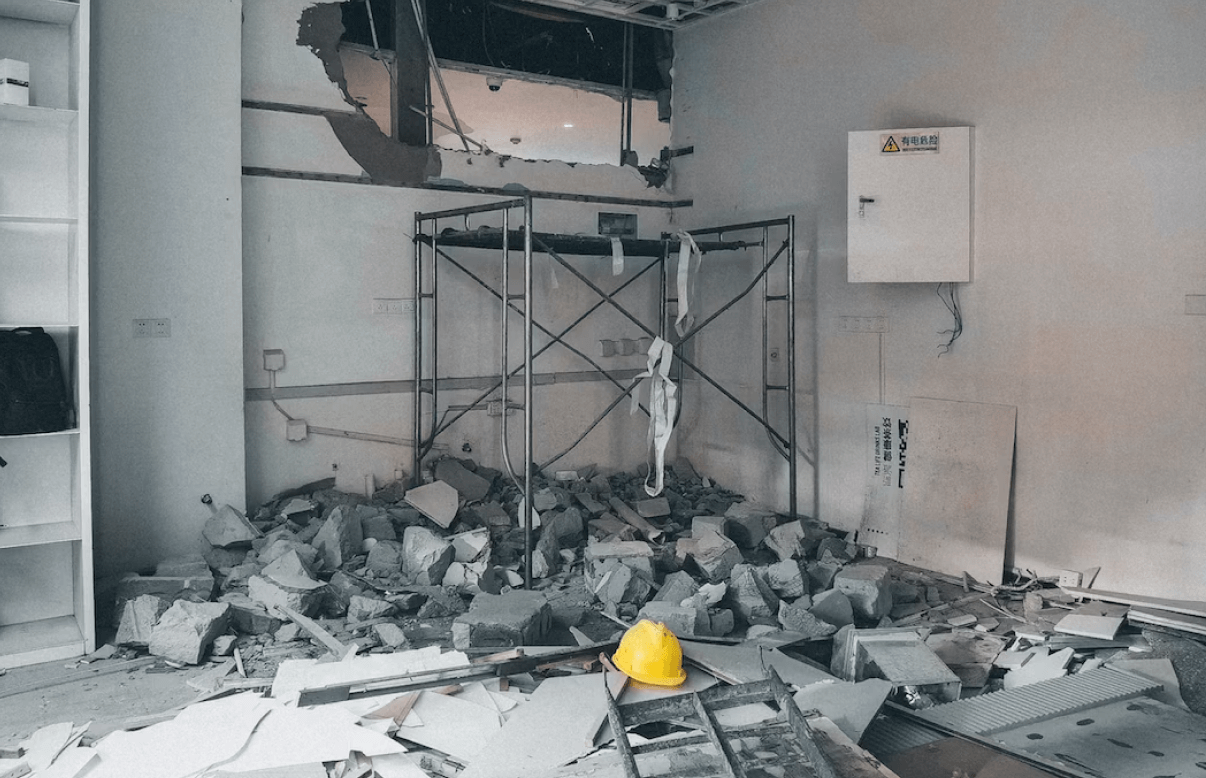

Example of an Abatement Process

The heart of a successful asbestos abatement process lies in the meticulous setup of abatement containment, adequate protection of workers, and ensuring that asbestos fibers do not spread beyond the designated area. Below, we show what a thorough abatement process for ACMs (asbestos-containing materials) looks like – from pre-abatement documentation through waste disposal and beyond.

Pre-Abatement Documentation

Asbestos Inspection Report:

Abatement Plan:

Regulatory Compliance:

- Conduct a thorough asbestos inspection of the area before abatement.

- Document the location, type, and condition of asbestos-containing materials (ACMs).

Abatement Plan:

- Develop a detailed abatement plan specifying removal method, containment procedures, and safety measures.

Regulatory Compliance:

- Ensure compliance with local, state, and federal regulations related to asbestos abatement.

Abatement Containment:

Containment Setup:

Ventilation System:

Personal Protective Equipment (PPE):

- Establish a containment area using plastic sheeting, negative air pressure units, and airlocks.

- Clearly demarcate the containment boundaries.

Ventilation System:

- Develop a detailed abatement plan specifying removal method, containment procedures, and safety measures.

Personal Protective Equipment (PPE):

- Ensure that workers inside the containment area wear appropriate PPE, including respirators, coveralls, and disposable gloves.

Decontamination Procedures:

- Implement decontamination procedures for workers exiting the containment area.

- Document the decontamination process.

Air Monitoring:

Air Sampling:

Periodic Inspection:

- Conduct air sampling inside and outside the containment area to monitor asbestos levels.

- Document sampling locations, frequency, and results.

Periodic Inspection:

- Regularly inspect the containment area to ensure its integrity and address any breaches promptly.

Waste Disposal:

Proper Disposal:

- Document the proper disposal of asbestos-containing materials according to regulatory guidelines.

- Use licensed asbestos disposal facilities.

Post-Abatement Documentation:

Final Inspection:

Clearance Sampling:

Completion Report:

Record Keeping:

- Perform a final inspection to ensure all asbestos has been removed and the area is safe.

- Document the completion of the abatement process.

Clearance Sampling:

- Conduct clearance sampling to confirm that asbestos levels are below regulatory limits.

- Document the results for future reference.

Completion Report:

- Prepare a comprehensive report detailing the abatement process, including methods used, any issues encountered, and corrective actions taken.

Record Keeping:

- Maintain detailed records of all abatement activities, including plans, inspections, air monitoring, and waste disposal.

Continuous Training & Improvement:

Employee Training:

Review & Update Procedures:

- Ensure that all personnel involved in asbestos abatement receive proper training.

- Document training sessions and certifications.

Review & Update Procedures:

- Regularly review and update asbestos abatement procedures based on lessons learned and changes in regulations.