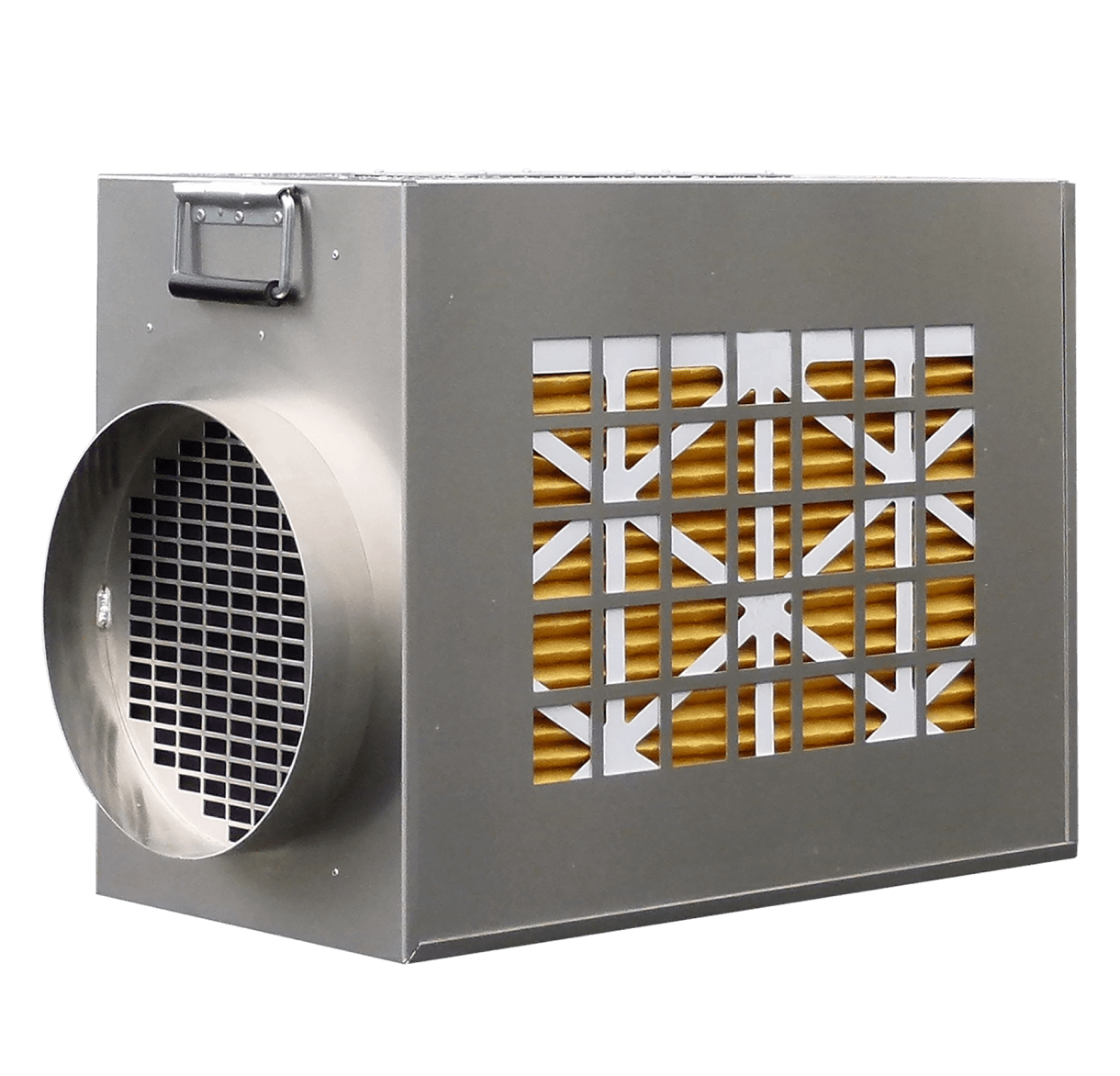

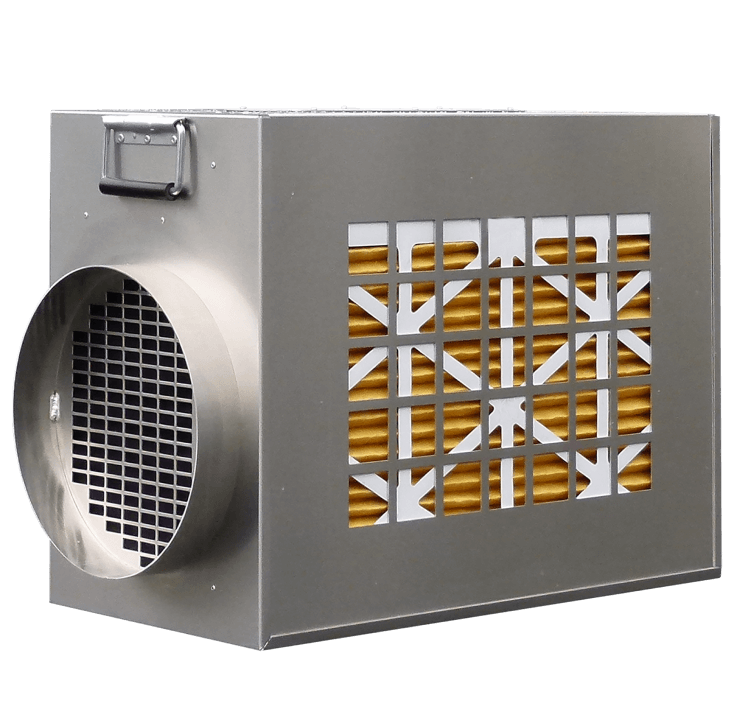

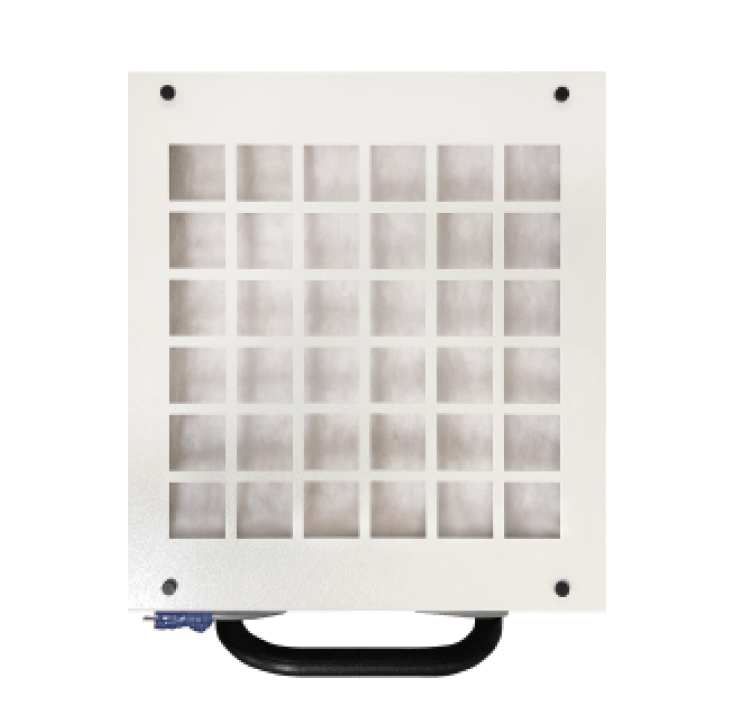

Surface and Air Cleaners play a vital role in maintaining air quality within agricultural, food, and medical facilities, addressing challenges such as the removal of odors and reduction of pathogen particles. To ensure the optimal performance of AgriAir® Surface and Air Cleaners, meticulous attention to CFM calculations is essential. These calculations determine the volume of air treated per minute, influencing the efficiency of the equipment in tackling specific contaminants. To ensure precise CFM calculations, AgriAir® devices state CFM using our exclusive TrueCFM™ ratings.

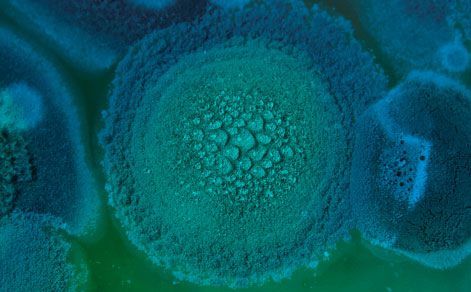

Various issues, including the control of mildew, mold spores, volatile organic compounds (VOCs), and other bio-contaminants, demand specialized equipment beyond basic HEPA and Carbon filtration. Air cleaner systems by AgriAir also harness the power of ionic oxidation technology to fight common airborne contaminants, both in the air and on surrounding surfaces. AgriAir cleaners not only pull particulates from the air drawn into the unit but generate and release hydro-peroxides into the surrounding grow environment. This cuts down on cross-contamination and the spread of mold spores and mildew.